JFE Ultrasonic Hardness Tester

Maintenance for large-scale structures, vehicles, ships, steel towers, bridges, aviation aircraft and so on carried out by making hardness measurements.

Used for measuring the hardness difficult to get at areas, grooved areas and internal R-sections of compact parts, metal casts, gears, crank shaft and component parts

Used for measuring the hardness difficult to get at areas, grooved areas and internal R-sections of compact parts, metal casts, gears, crank shaft and component parts

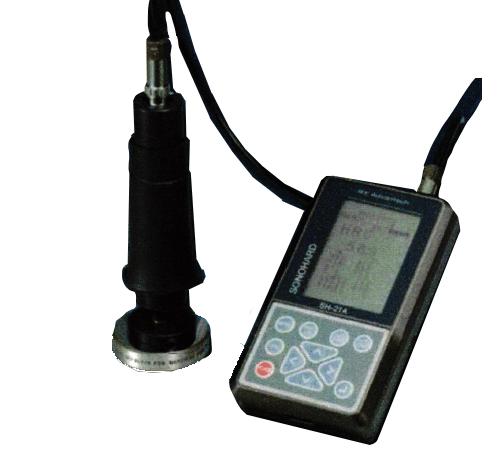

SONOHARD SH-21A

feature

- Measurement possible in just a few seconds.

Makes it possible to reduce measurement time. - Extremely minute indentations (approximately 0.1mm2)

Can be used for product inspections, as indentations are virtually unnoticeable. - Direct reading of hardness values (HV. HRC, HS. and HB).

The hardness value can be obtained with one measurement without using calculation formulas. - Conversion to tensile strength (N/mm2)

The level of the strength of materials can be converted according to tensile strength values. - Measuring tables (wooden, iron, resin, etc) do not affect measurement.

Can be used without worrying about the location of measurement. - The backsides of test samples do not affect measurement.

Measurements can be made without being influenced by the backside of work pieces. - Data can be stored in memory up to 2000 pieces.

Data can be managed easily using customer’s own developed software of data transfer to PC. - 10 pieces of calibration memory.

It is not necessary to re-calibrate every time the nature of the work changes. - The handy recharge pack makes it easy to carry out on-side measurements.

This makes it possible to measure steel towers, ships, large-scale parts, complexly arranged parts and other items both indoors and outdoors in their natural state. - Free measuring ability in all directions.

Not only vertically and horizontally but all directional measurements can be made without any compensation. - Beneficial to reducing costs by making periodic part replacement unnecessary.

Static pressure types of loads eliminate the need for temporary parts and annual replacement. - Hardening and annealing can be controlled according to hardness levels.

It is possible to check the state of hardening and annealing of repaired metal casts according to their hardness levels. - Possible to make output to an external printer (optional).

This makes it possible to quickly record measurement data using a printer on site. - Upper and lower limit alarms can be established.

It is possible to set up alarms to notify if the allowable limits of a work piece have been surpassed.

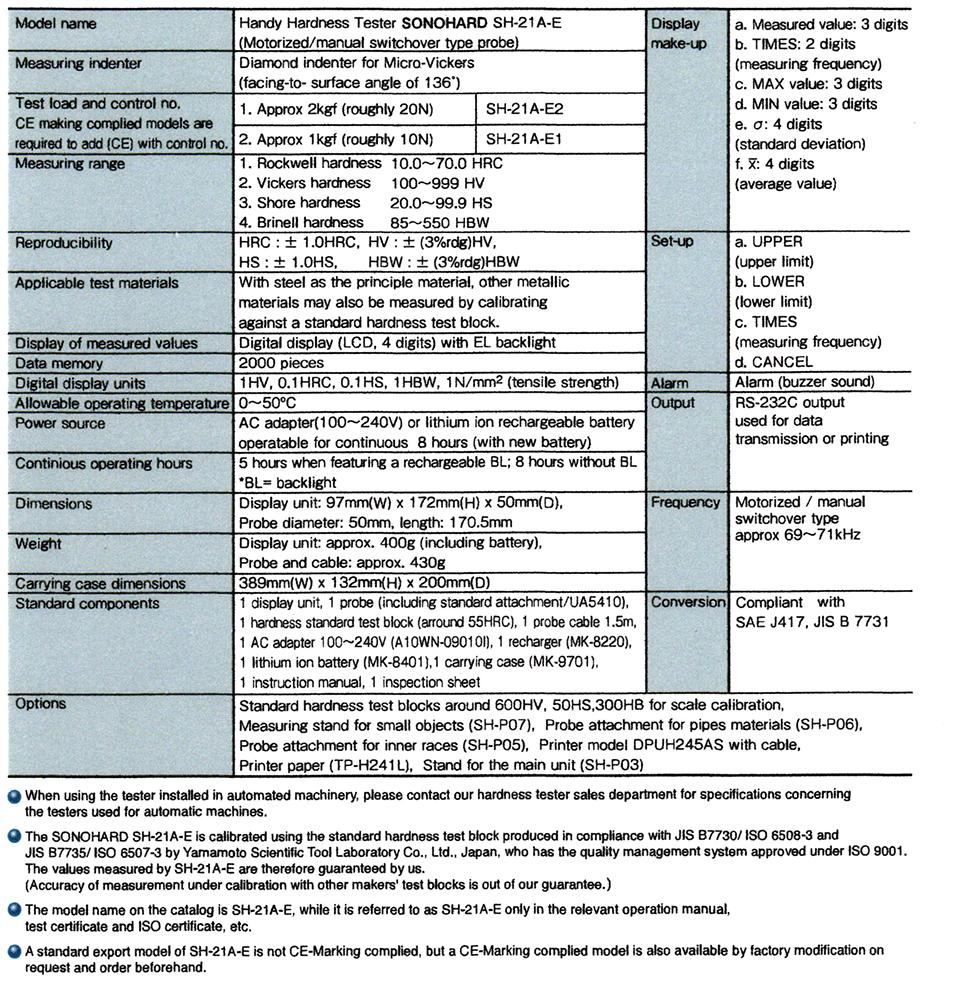

spec

For a better look click on the image above.

For a better look click on the image above.

PDF Download

- SONOHARD SH-21A